In my last post, I initiated coverage of Algoma Steel (NASDAQ:ASTL), explaining my reasoning that through Algoma Steel’s current cost model with its Basic Oxygen Furnace, it is fundamentally undervalued by the market. Along with its current production output, due to its ongoing Plate Mill Modernization efforts and its transition to Electric Arc Furnace, Algoma will significantly expand production, increase margins, lower carbon tax costs, and decrease maintenance costs.

This article is for updating my thesis as Algoma Steel reported Q2 2024FY Earnings on Thursday, November 2nd, and posted guidance for the quarter on September 28th.

Earnings Results Vs. My Estimates

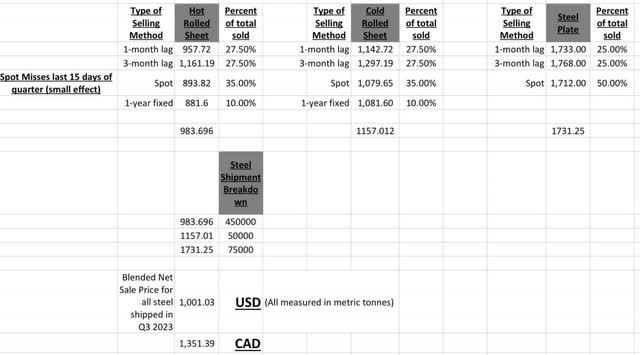

As a reminder, here was my net sales pricing model

Steel Price Estimate for Q2 2024FY (Steel price indices and Algoma Steel calls)

When I combined these prices with a prediction of $990 CAD/MT cost profile, I estimated EBITDA should be roughly $200M CAD considering 550k-555k metric tons shipped. This also assumed a cost per metric ton of steel products sold of $990 CAD.

Instead, they posted 549k in shipments (minor effect) and a shocking $81M CAD in adjusted EBITDA. Not horrible considering the industry-wide downturn in the quarter due to UAW strikes, but lower than I expected.

I will first admit that part of my error was purely mathematical in that for spot pricing, I neglected the last two weeks of the quarter in my average instead of using September 15th pricing for the remaining two weeks. This would’ve decreased my Net Sales Realized (NSR) per ton by about $30 CAD/MT, not significant but still worth pointing out.

The main reason that my calculation of $1351.4 CAD/MT differed from the actual NSR per tonne of $1,213 CAD is due to the UAW strikes hurting auto production. Though the majority of these depressed prices were included in my calculation, likely due to seasonal timing, shipments were more concentrated during this time. Along with this, given less auto shipment, middle-market steel distributors likely became the second best option for excess short-term production. Luckily, this problem is behind us.

Though that solves the issue on the pricing side, the cost per ton of steel products was $1,020 CAD/MT, a $30 CAD/MT difference versus my estimate. This was primarily a result of an increase in commodity input cost. For one, natural gas costs increased 20% over the quarter, affecting direct purchases and electricity costs. Secondly, purchased coke prices increased as coal prices saw an increase in the latter half of the quarter. Finally, given that shipments were 1%-2% less than expected, fixed costs per metric tonne increased, accounting for roughly a third of the differential.

Mediocre Earnings, Though Significant De-risking And New Milestones

Though earnings weren’t exactly stellar, a significant amount happened during the quarter which has significantly de-risked Algoma Steel’s prospects, still making them extremely undervalued, in my opinion.

Market Outlook

Results in the quarter were against a challenging backdrop in the markets with pricing impacted by the UAW strike. Prices currently hover around $1,000 USD/MT for Hot-rolled Steel Prices, an attractive market looking forward, especially when compared to last quarter.

Plate Mill Modernization Update

In the second quarter of 2024FY, commissioning and testing of the heavy gauge inline shear occurred showing continued Phase 2 PMM progress. This resulted in $54.9M of capital expenditures being incurred for the PMM. Algoma is still on track to ramp production up in late November or Early December. I believe end-of-year plate volumes likely will increase 10%-15% without significant disruption. It should be noted that expenses and efficiency effects from phase 2 likely impacted results in this quarter even though all “real” costs are capital expenditures mentioned.

Along with this, Phase 2 has been de-risked as the original plan of a 40-day outage has been split into two 20-day outages, though there is a slight day with the first outage in April as planned and the second outage will be later in the year.

It should be noted the plate pricing premium has still been maintained had historical highs and it doesn’t make sense from a risk and cost-benefit analysis to undergo outages right now considering how attractive the steel plate market is for Algoma.

Raw Material Inputs

Algoma received a 2-year extension for its iron ore purchase contract with U.S Steel, with an option for third year, covering all future iron ore needs during the transition to EAF. For coking coal, 2024CY contracts have been settled and pricing will be down in the low teens in 2024FY.

Another thing to consider is the July 2022 5-year labor agreement was just another event outlining that compared to the average independent steel producer, Algoma Steel has great security of inputs. Winter months will naturally see some higher costs, but as we go into next year, costs will begin to come down. Overall, from a cost and input security perspective, Algoma is in a much better place.

Electric Arc Furnace Update

As of September 30th, 2023, $456M, or 54% of EAF project expenditures have been spent. 80% of the budget is under contract, with 100% expected to be contracted by the end of March 2024. Only 5% of the contracted amount is subject to time and material adjustments with the rest being fixed price.

EAD Commissioning is still expected in late 2024CY with ramp-up of steel production throughout 2025CY. Current Steel Shipment run-rate is 2.2M – 2.4M metric tons and once the EAF is installed, they can keep at this run rate without relying on the blast furnace, using only on-site generation and the current grid, with opportunistic use of blast furnace providing upside. This is pretty big news as though they are still going to be in alternating mode for 3-5 years following EAF commissioning and this run rate for EAF was already established, the important detail is that they will be able to operate the EAFs independently during this period if they would like to, showing that they have established significant security in electric grid connections

They received a system impact assessment for the second phase of EAF (2030-2031 full operation phase) during the quarter. They concluded that when the local 230 cable is installed, the EAFs will be able to run without the need for on-site power generation which improves energy reliability even more.

Along with this, I mentioned it in the comments of the last post but there was controversy between Algoma/Sault Ste Marie government and Ontario Grid over power availability post 2026. This has been resolved as the Ontario government announced the acceleration of regional power infrastructure to meet local demand. What this means is that even though the plan is for hybrid production, they just want to emphasize that they can operate fully on grid power during this phase before the full upgrade. Still, considering fixed costs, blast furnaces will operate on a reduced capacity as it makes sense from an economical perspective.

The final cost of the project remains at $828M – $878M CAD, with there being $397M CAD to be spent, with $93M in SIF loan capacity available. Approximately $150M from Working capital liquidation will occur, with 70% of this will be in the next two quarters. Another notable thing is that we got more info about carbon tax cost with total taxable emissions of 200k for $13M CAD in annualized carbon taxes with it going up $3M a year for the next 7 years, once again showing a major saving the EAF transformation will give.

Shipments

In the next quarter, shipments will decrease approximately 20k – 30k metric tonnes due to non-seasonal maintenance.

Changes In Valuation

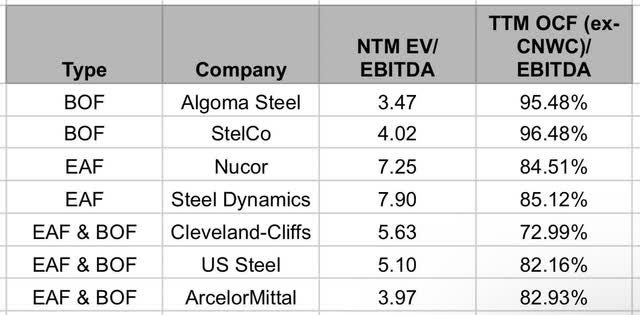

In my last analysis, I utilized a peer-based valuation which though I believe is still valid, I would like to show what valuations look like from a forward perspective using analyst estimates:

Algoma Steel Peer comparison (Tikr.Terminal)

Through using the next twelve months estimates, a better picture of financial performance in this tumultuous steel market is seen. I also provided a trailing statistic showing operating cash flow conversion from EBITDA, with Algoma Steel and Stelco being the leaders by far. This is important as it reveals the flaw in EBITDA as BOF producers tend to have higher maintenance expenditures and higher cash flow conversion.

Though I believe it is too early in the quarter to estimate results, the hot-rolled coil indices have breached $1000 USD/T. Along with this, the cold-rolled premium has widened to roughly $300 USD/T and the steel plate premium is at $650-$700 USD/T. Given the slightly better conditions in the steel market and the future growth points for Algoma Steel, I still believe that a price target of around $15 USD per share is fairly conservative for the next couple years.

Risks

The primary risk to my thesis is that Algoma Steel is a cyclical company and is affected by the many factors affecting the broader steel market, though this is mitigated by having strong milestones for potential growth.

Regarding these milestones for growth such as the plate modernization and EAF transition, there is risk regarding the timelines of these projects along with their budgets.

Conclusion

In conclusion, I view Algoma Steel as a greatly undervalued opportunity in the Steel industry not only because of its predicted $340M CAD in EBITDA or 35% of the market cap over the next year at the minimum but also because of its plate modernization and Electric Arc Furnace projects. Though this quarter missed expectations, it was largely due to one-off events. Meanwhile, through securing raw materials in new contracts and better energy supply with the Ontario government, Algoma’s future has been de-risked significantly and I believe they are still a very attractive opportunity.

Read the full article here